New Paper out

New publication out coauthored by Prof. Markus Bambach.

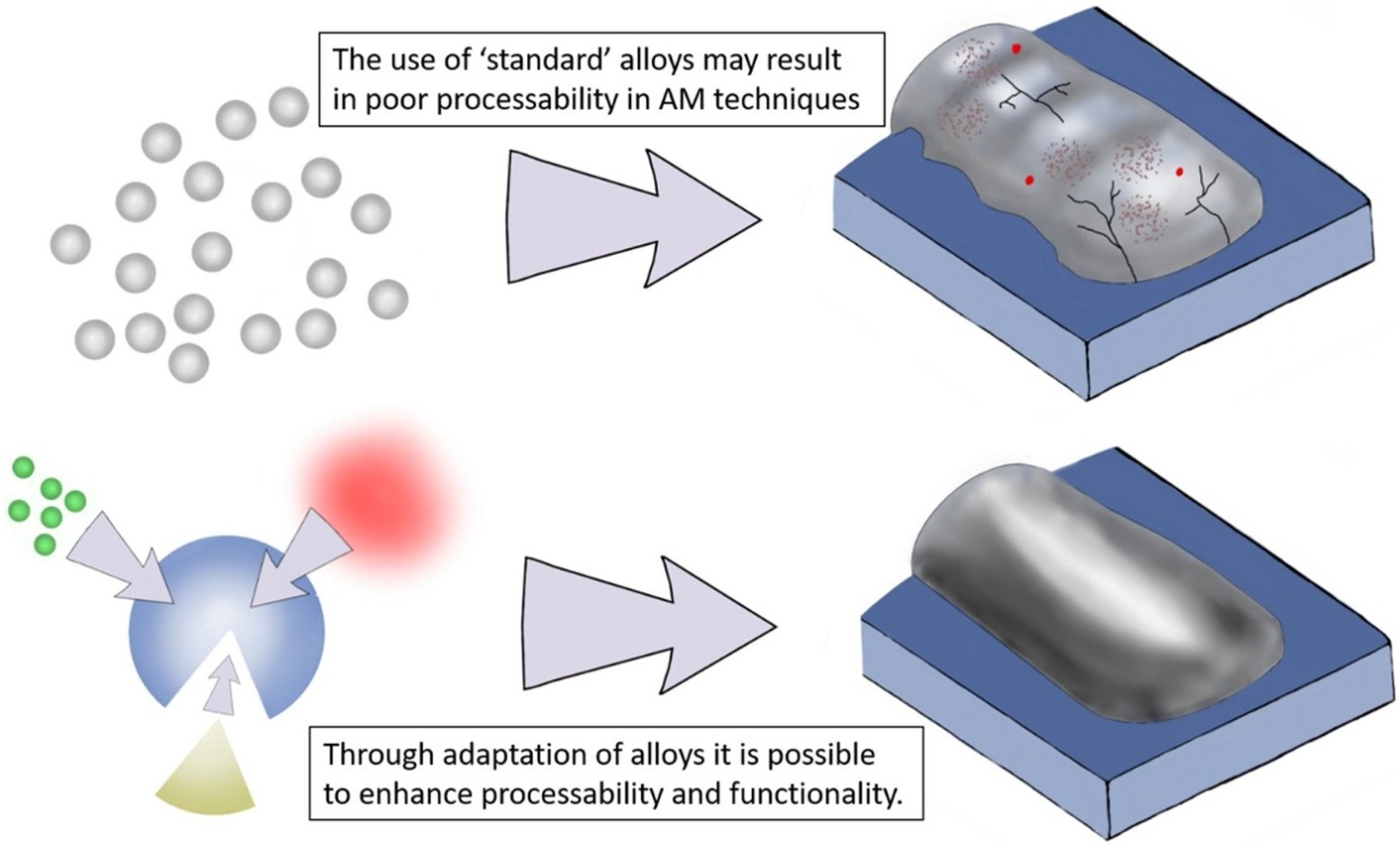

Alloys originally developed for conventional processes are often chosen as the starting point when designing a part for additive manufacturing (AM) by DED or LPBF. Such alloys are suboptimal, however, in consideration of the thermal gradients and cooling rates encountered in AM, which lead to high residual stresses, cracking, anisotropic texture, and evaporation loss of alloying elements. This external page work, coauthored by Prof. Markus Bambach, reviews the thermal evolution encountered during the AM process and proposes several approaches to designing AM-specific alloys with superior properties.