New Paper Out!

New paper out on process optimization of multi-material 3D structures fabricated by spark plasma sintering,

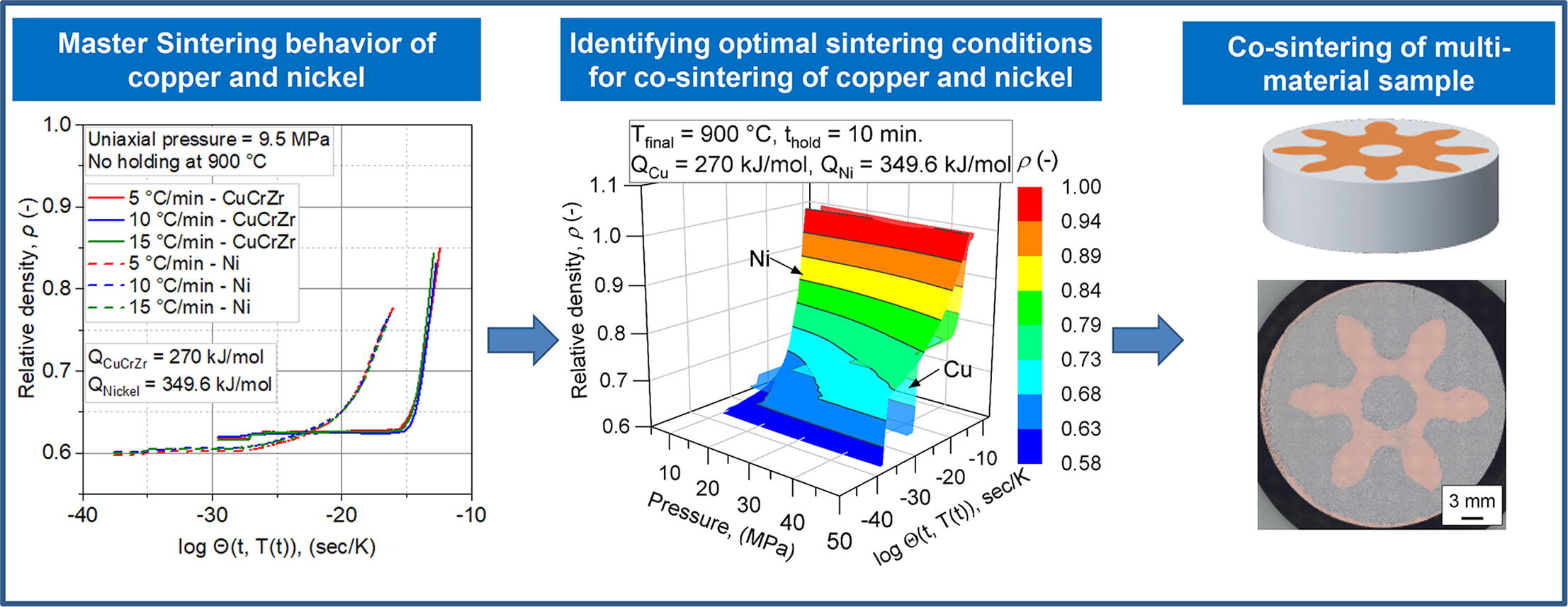

There is growing interest in the manufacturing of multi-material components, as those are found in many industrial sectors such as in the medical, in aeronautics or for electric connections and heat exchangers, where they are designed to take advantages of two or more materials. However, most current designs require joining operations, which are not only costly but also tend to be challenging as the level of dissimilarity between the two materials to be joined increases. The design freedom offered by additive manufacturing (AM) processes is naturally appealing for multi-material components too, where they would furthermore allow the integration of functionality into a design, but AM processes that allow for the manufacturing of multi-material components are still very limited. Moreover, some material combinations are expected to be very challenging to co-process by melting-based AM processes due to high differences in physical properties, and hence, alternative manufacturing routes need to be considered. In the present manuscript, we show that spark plasma sintering can be used successfully to produce dense multi-material 3D structures made of dissimilar materials such as CuCrZr and nickel, and we present a methodology to determine optimum co-processing parameters.

Check the full paper external page here