New Paper out!

New publication out on Algorithmic determination of measurement locations in sheet metal forming.

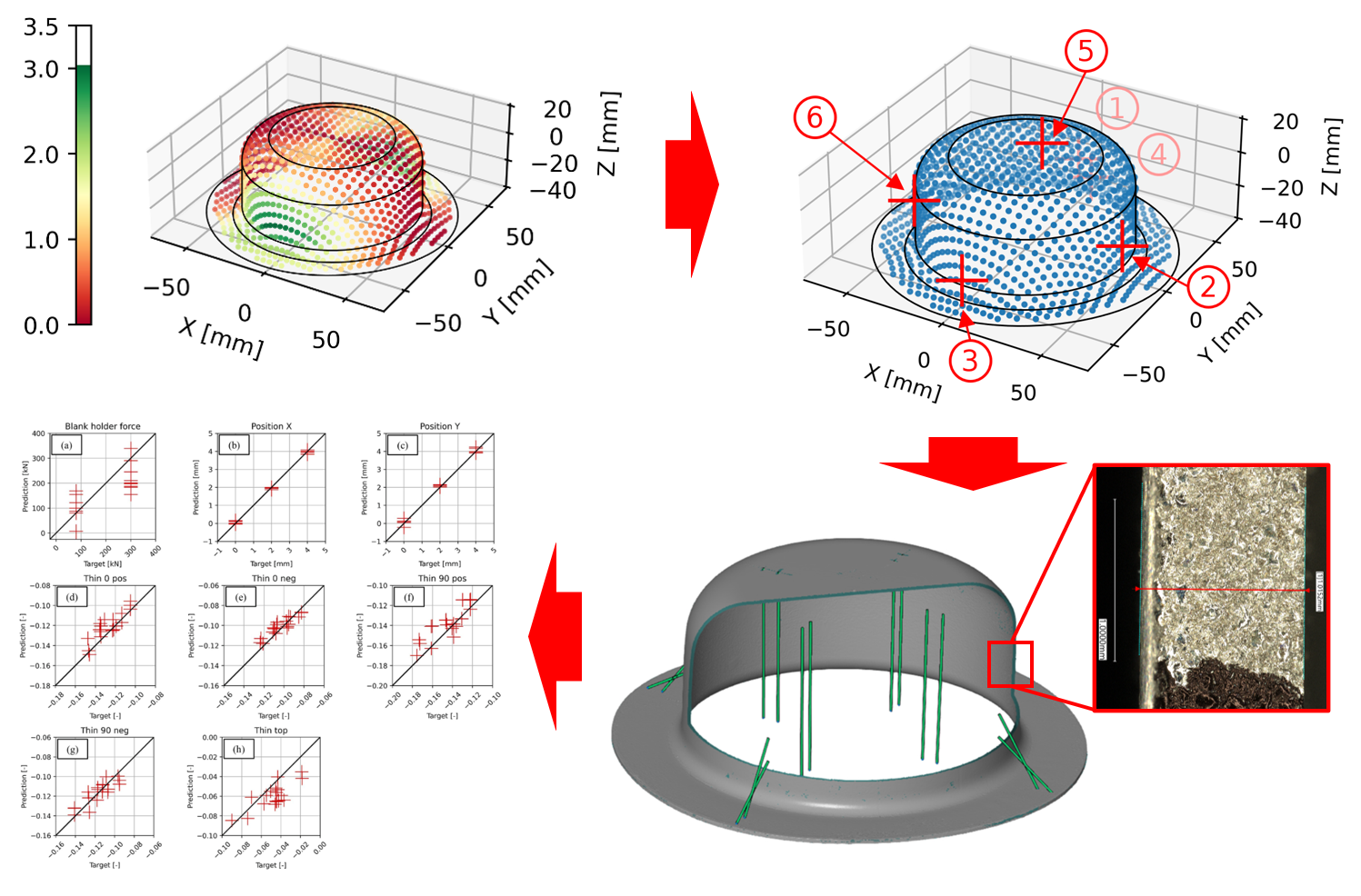

The observable used most often in deep drawing is the movement of the sheet border, which is referred to as draw-in. Due to the usually large distance between the sheet border and the areas of the largest plastic deformation, literature provides indications that more representative locations for the characterization of the material flow exist. In this work, a novel algorithmic method is proposed that allows to determine the optimal locations at which the material flow should be measured. The method is applied on surface markers on a cup, whose displacement is measured ex situ using a stripe projection scanner. The indications in the literature are confirmed, with the most sensitive markers found in, or directly above the die radius in the side wall of the cup, where an increase in the sensitivity of the marker displacement by 51% compared to the draw-in is observed. A comparison of markers positioned at different radii on the initial sheet reveals a clear correlation between the sensitivity of the markers and the predictive accuracy if their displacement is used as observable to predict the sheet thickness and process parameters in an inverse manner. The application of the methodology applied on industrial parts will be part of a future project in cooperation with the automotive industry.

Check the full paper external page here.