New paper out!

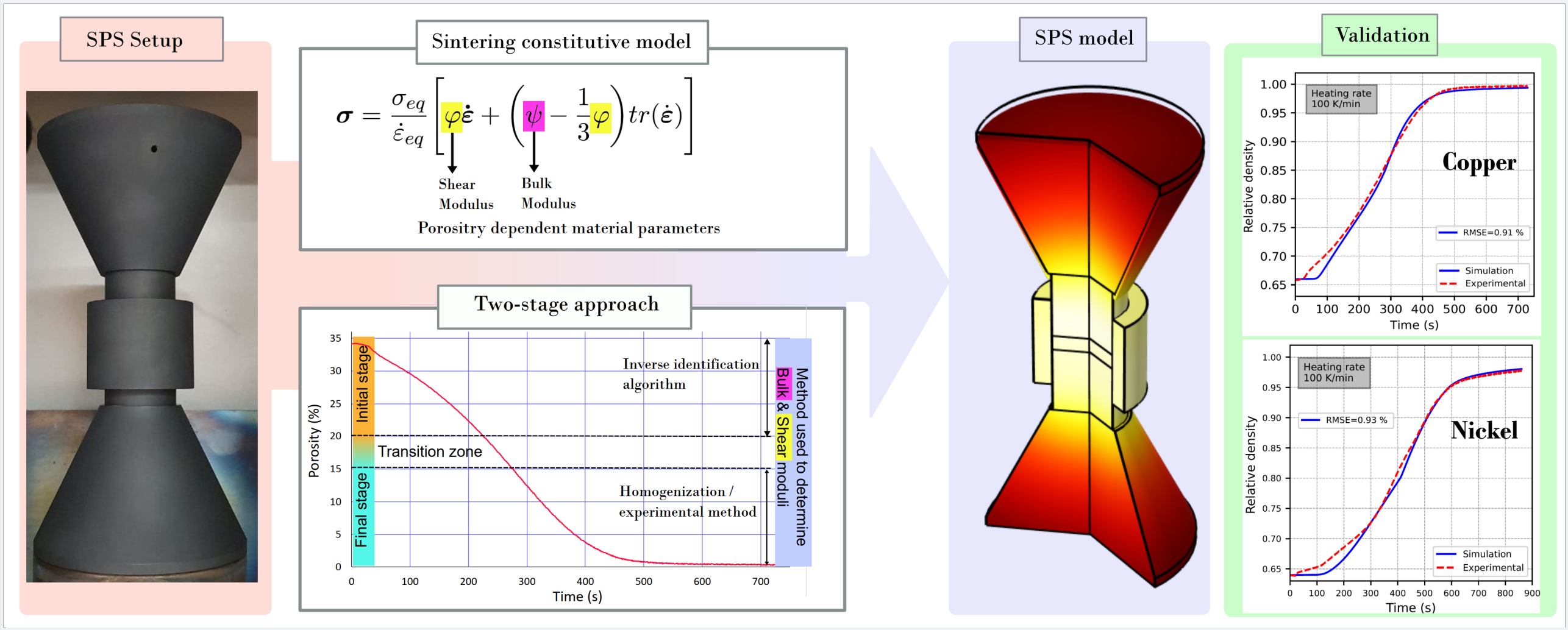

New publication on a two-stage approach to parameter identification in spark plasma sintering.

In the sintering process, the density varies throughout the process, making it difficult to identify the correct material parameters for simulation.

In this paper, a two-stage approach is proposed that integrates direct experimental measurements with numerical simulations to provide a more comprehensive and reliable basis for identifying the material parameters in spark plasma sintering (SPS) process. A finite element based fully coupled electrical-thermo-mechanical model is developed and experimentally validated, which achieves an average prediction error of less than 1.5% when applied to copper and nickel SPS at different heating rates from 25 to 100 K/min.

Read more external page here.