New Paper Alert!

We are excited to share our latest research: "Sensor placement utilizing a digital twin for thermal error compensation of machine tools" is published in the prestigious Journal of Manufacturing Systems!

We are excited to share our latest research: "Sensor placement utilizing a digital twin for thermal error compensation of machine tools" is published in the prestigious Journal of Manufacturing Systems! 🏭🔧

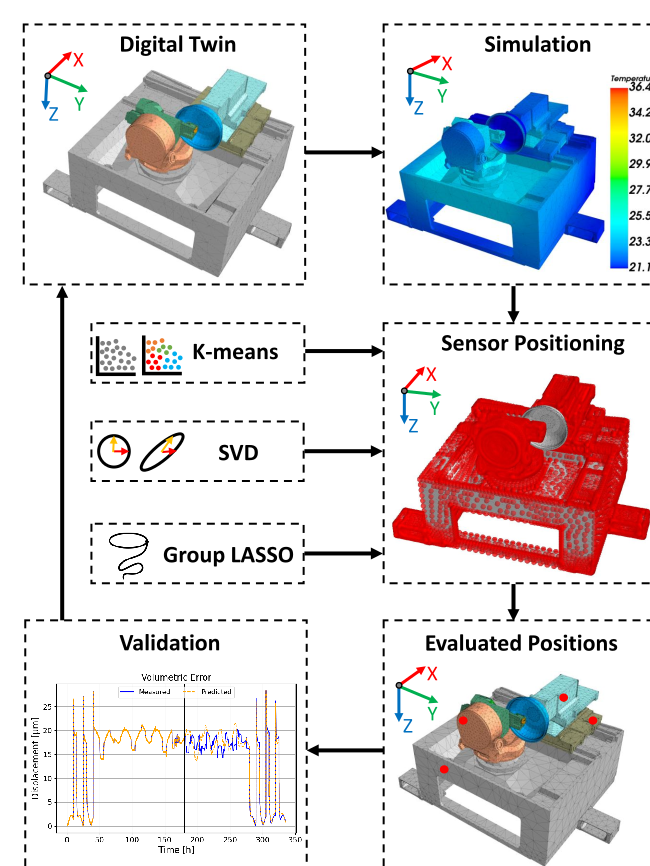

Thermal errors are a major challenge in precision manufacturing, affecting accuracy and efficiency. Our study introduces a digital twin-based method to optimize temperature sensor placement, significantly reducing sensor count compared to manual positioning (from 22 to just 7!) while improving compensation accuracy.

✅ Key Highlights:

🔹 Uses ensemble simulations to identify the most effective sensor locations 📡

🔹 Reduces thermal error by up to 85% on real machine tools 📉

🔹 Combines Singular Value Decomposition (SVD) and Group LASSO for smarter sensor selection 🧠

🔹 Improves energy efficiency and sustainability by reducing warm up time and scrap 🌍💡

💡 Why it matters?

This approach makes thermal error compensation more efficient, robust, and cost-effective—a step toward more autonomous and sustainable precision manufacturing! 🚀

🙏 Big thanks to the authors Sebastian Lang, Mario Zorzini, Stephan Scholze, Josef Mayr, and Markus Bambach, as well as our partners at Agathon AG and inspire AG for their support!

🔗 Read the full paper (open access!): external page https://doi.org/10.1016/j.jmsy.2025.03.003