Publication alert

New paper out “Identifying melt pool behavior in ceramics PBF-LB via operando synchrotron tomographic microscopy and high-fidelity process modeling”

This research was carried out by Zhilang Zhang and his master's student, Alexander Muther. The in-situ experiments were conducted by Makowska Malgorzata Grazyna from the Paul Scherrer Institute (PSI).

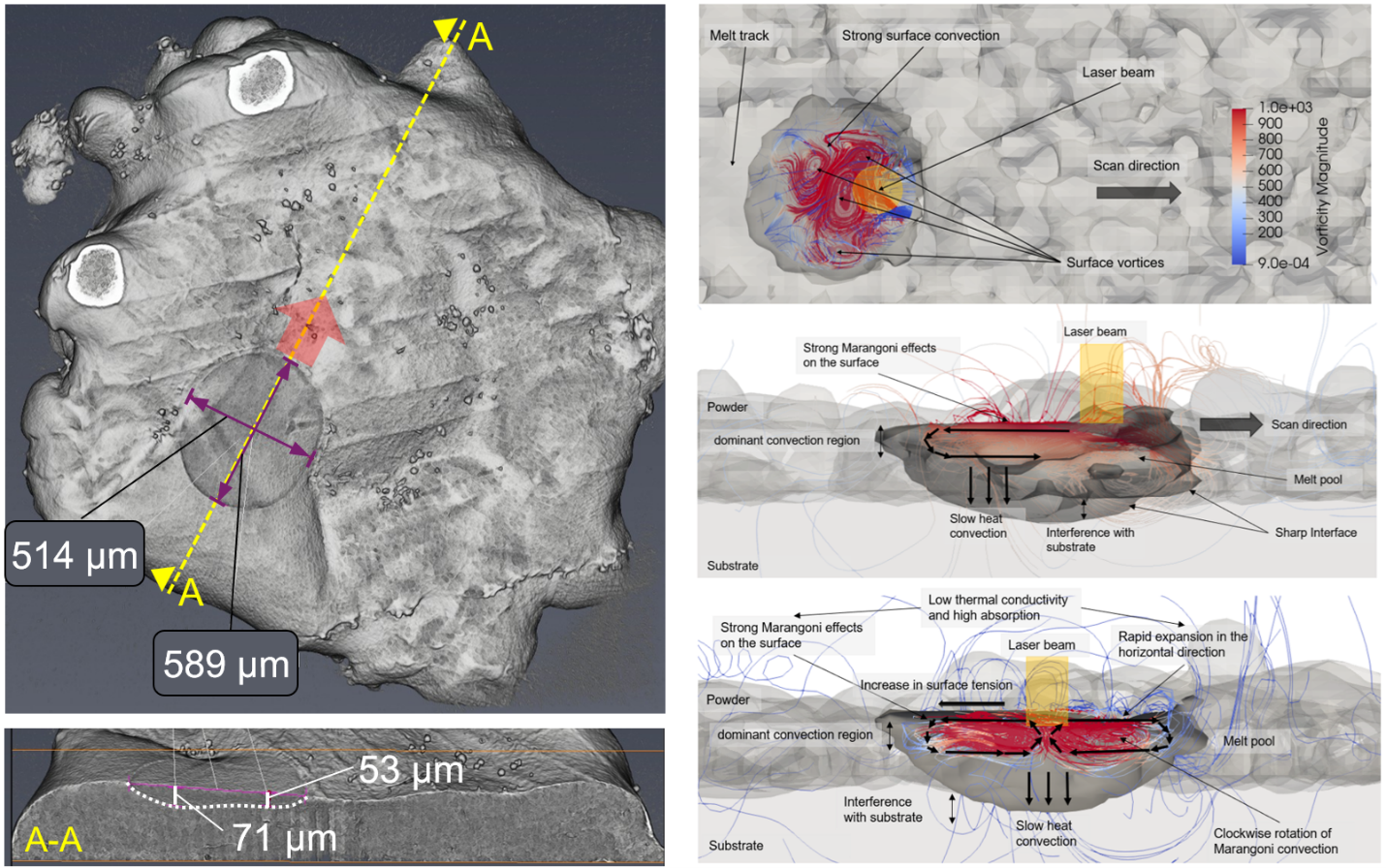

Abstract: Recent advancements in high-fidelity process simulations have significantly enhanced the understanding of melt pool behavior during laser-based powder bed fusion (PBF-LB) of metals. However, for ceramics, their unique material properties and complex thermophysical behavior present significant challenges in developing detailed models that effectively complement limited experimental observations. In this work, we integrate operando synchrotron X-ray tomographic microscopy with computational fluid dynamics-discrete element method (CFD-DEM) simulations to investigate the melt pool dynamics of alumina during PBF-LB. In-situ observations reveal a shallow and wide melt pool, distinct from that of metals. This behavior is linked to alumina’s low thermal conductivity, high laser absorption, and negative surface tension gradients, as confirmed through high-fidelity process simulations. Key mechanisms identified include limited heat penetration, enhanced surface-oriented convection, and surface vortices driven by heat exchange with the surrounding gas environment. The influence of laser power and scanning speed on melt pool geometry is systematically analyzed, leading to the first virtual process map and parameter windows for stable PBF-LB of alumina. These findings provide critical insights for optimizing process parameters and advancing ceramic additive manufacturing.

external page Link of full paper.