AI & Digitization

Reinforcement Learning based Path Planner

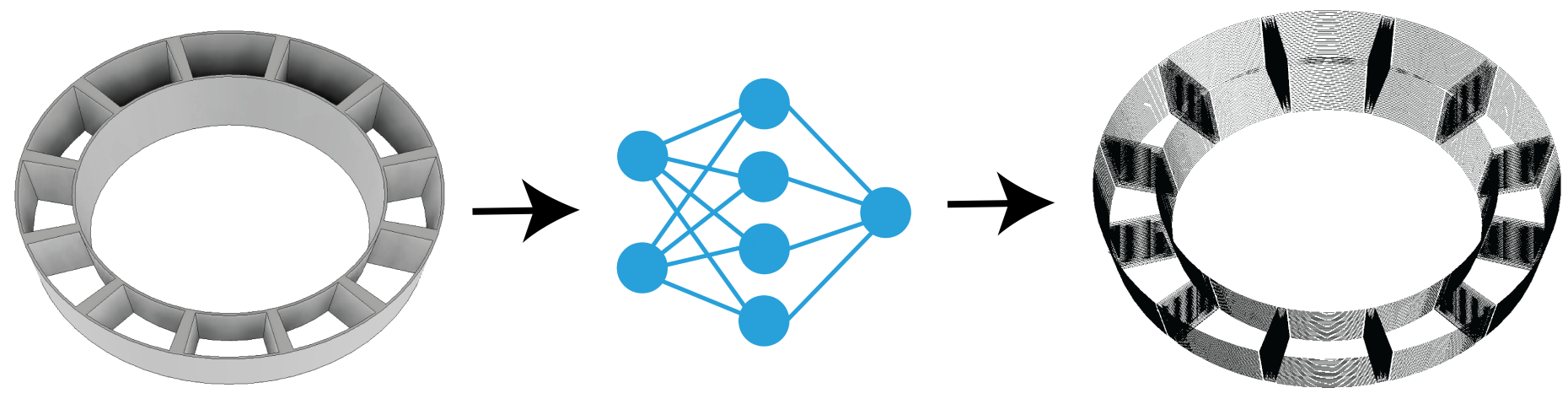

The aim of this project is to develop an algorithm that proposes a deposition path using artificial intelligence. Specifically, reinforcement learning is used, where the input to the algorithm is an STL file and the output is the deposition path together with the printing speed. The goal of this project is to save time and fully automate the path planning process, which currently involves a lot of manual work.

In addition, compared to the currently used planning softwares, the proposed solution allows to change the printing speed along the deposition path, which allows to adjust the size of the weld bead according to the need. Last but not least, the algorithm is designed so that it can be used for various additive technologies and is not focused only on one specific application.

Contact: Jan Petrik

Data-Driven Optimization of Temperature Fields

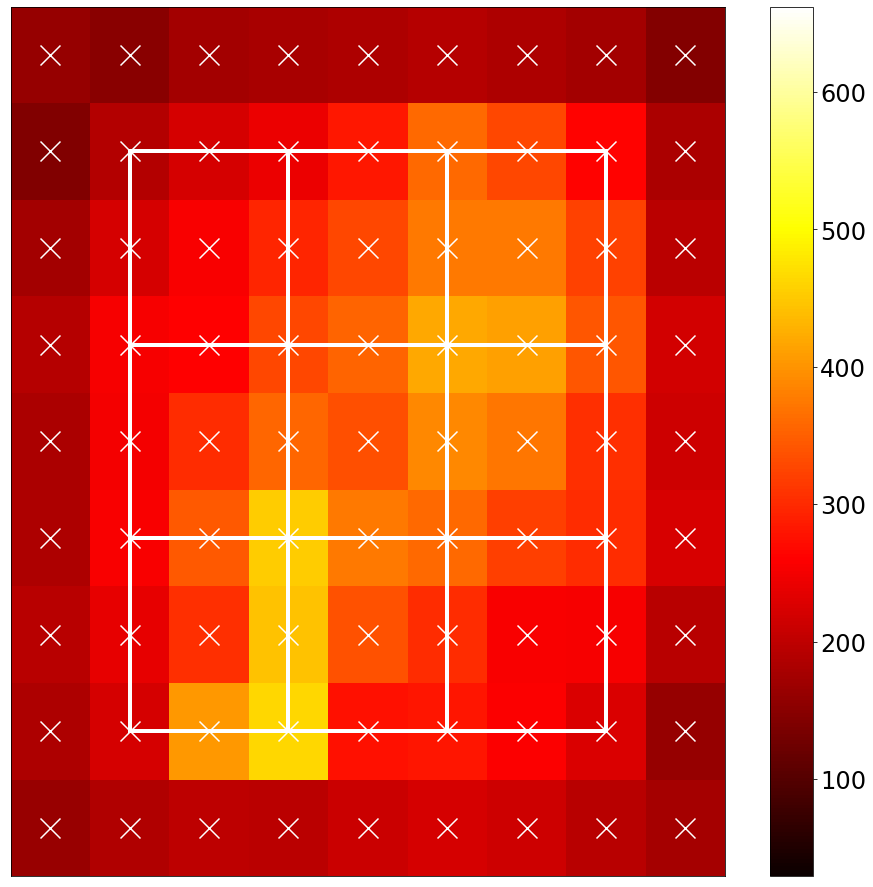

This project aims to leverage the power of modern data-driven algorithms and optimization for achieving homogeneous temperature distributions in Metal Additive Manufacturing applications.

Data efficiency, low computational complexity, and interpretable results are critical traits in shaping industry-ready models capable of being used in a wide range of different scenarios for thermal predictions. Coupling these models with iterative optimization algorithms enables improved quality in produced parts at an acceptable cost.

Contact: Sideris Iason