Forming Technology

Manufacturing of Bipolar Plates for Fuel Cells

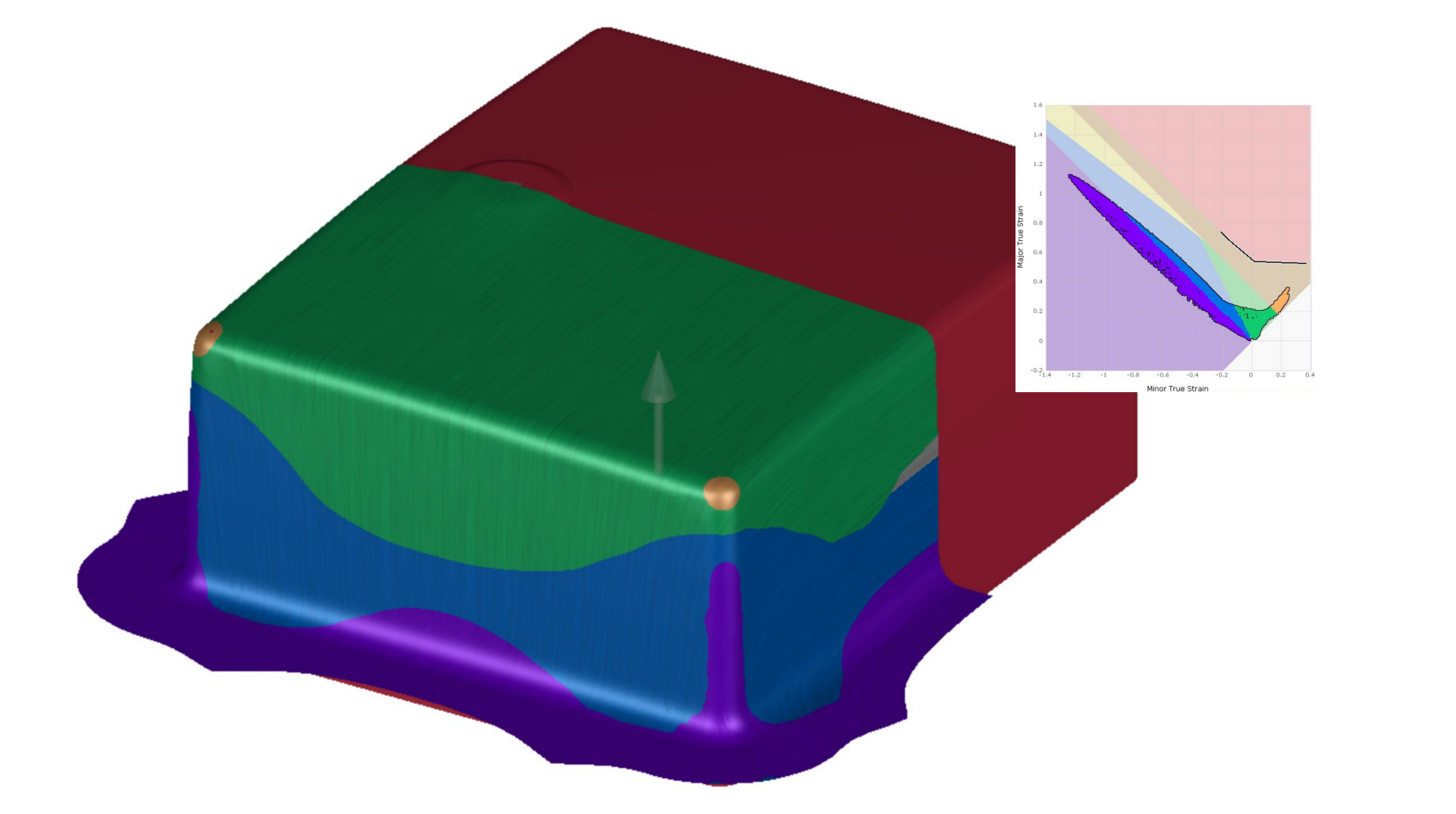

Bipolar plates are an essential part of fuel cells. Their purpose is to ensure the optimal flow of the products and educts for the chemical reaction (e.g. Hydrogen, Oxygen and Water), as well as conducting the electric current created by the cells and providing structural integrity. Stamping as a way of manufacturing these components is proving to be the most valid method to enable cost efficient mass production and therefore a more widespread adoption of the technology.

As the bipolar plates make up most of the final weight of the cell, there is an interest in using increasingly thin metal sheets (50-100μm). This combined with the high complexity in flow channel designs poses great challenges to virtually model the manufacturing process accurately and efficiently. This project therefore investigates various methods which aim precisely predict the formability and potential failure during the forming process, decreasing the construction and spotting time required to set up the production for bipolar plates.

Contact: Lukas Gassler

Expansion of the forming capacity of stainless steel through the targeted exploitation of its temperature dependence

The aim of the project is the development of a deep drawing process with an innovative tempering strategy to use the thermal dependency of the metastable austenitic stainless steel 1.4301 to expand the forming capacity.

To simulate the process, the material behavior (flow curve, yield locus, FLC) is measured for a wide temperature range and the material models are calibrated. In addition to the thermal dependence, the nonlinearity of strain paths caused by the process must also be considered when predicting failure. With this knowledge, a targeted expansion of the forming capacity can be done and a robust process window under the consideration of the temperature influence can be defined.

Contact: Konrad Barth