New paper out!

New paper published on the effects of beam shaping on copper-steel interfaces in multi-material laser powder bed fusion !

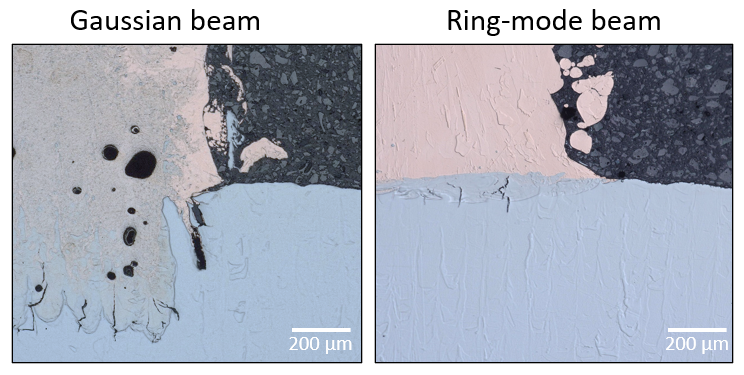

Enhanced component functionality can be achieved by combining materials with distinct properties – however this comes with a price, as significant mismatch in the material properties may also cause interface defects. Our latest research dives into the Copper-Steel combination, addressing an embrittlement phenomenon at the interface known as copper contamination cracking (CCC). We have pioneered the use of laser beam shaping in multi-material laser powder bed fusion, restricting material intermixing at the interface to a few tens of micrometers. This not only minimized interface defects significantly, but also modified the microstructure of the multi-material structure compared to a traditional Gaussian beam laser.

Click on the link to read more and enjoy full external page open access.