Publication alert

Correlation analysis of feedstock flowability and temperature for laser-based powder bed fusion of polymers

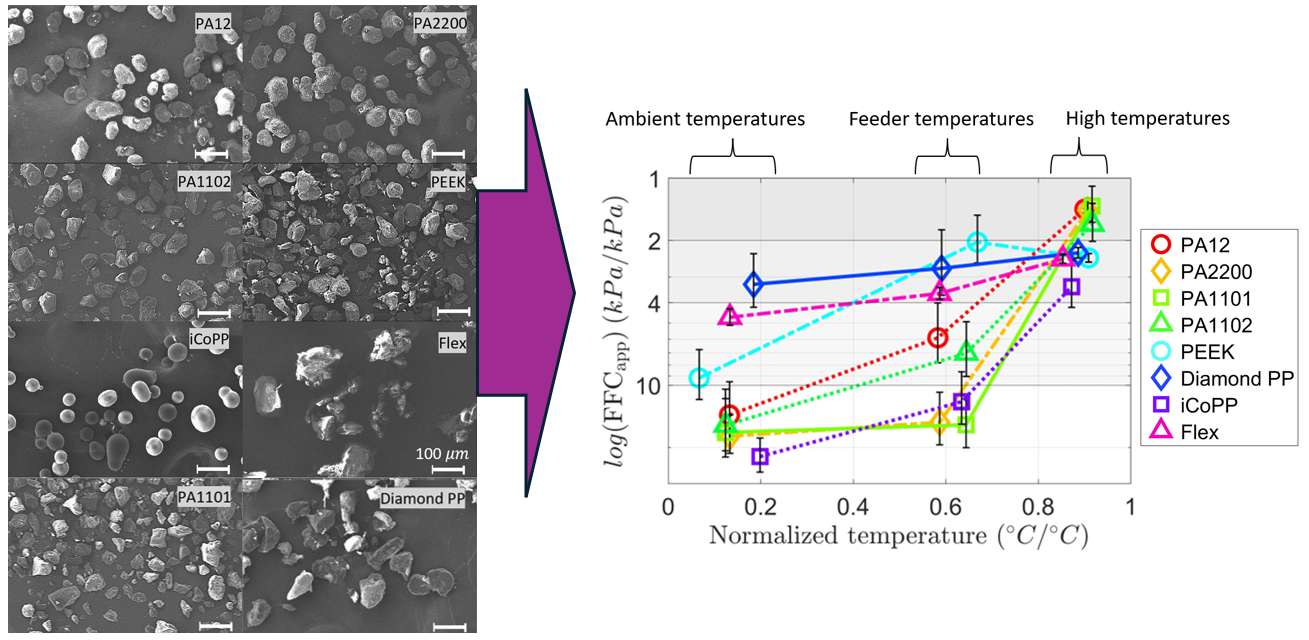

The study aims to improve the understanding of powder flowability in laser-based powder bed fusion of polymers (PBF-LB/P), a crucial factor for achieving high-quality parts in additive manufacturing. Accurate characterization of flowability is challenging due to varied testing methods and complex forces at play. This research investigates the flowability of eight feedstock materials across different temperatures using various techniques, including avalanche angle, Hausner ratio, approximated flow function coefficient (FFCapp), and differential scanning calorimetry (DSC).

Key findings indicate that material properties, such as mechanical softening near the melting point, significantly impact flowability, explaining why some powders with poor flowability at ambient temperatures still produce high-quality parts. FFCapp and DSC are identified as critical metrics for optimizing material characteristics across temperature ranges. The study emphasizes the importance of considering temperature in flowability analyses to better simulate the PBF-LB/P process, which can inform material design, selection, and process optimization. This approach contrasts with prior studies that mainly focused on ambient temperature characteristics or limited material selections, highlighting the value of incorporating temperature effects into flowability assessments.

Link to external page full paper