New paper out!

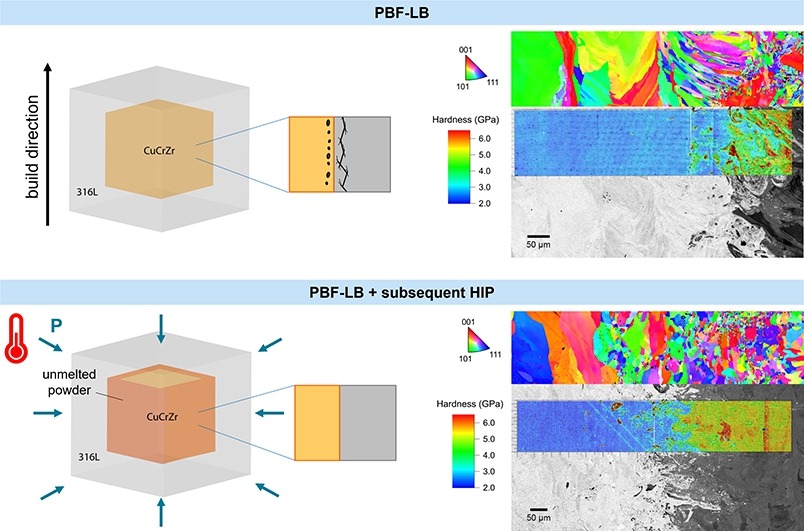

New publication on a new strategy to produce defect-free CuCrZr-316L steel multi-material structures by coupling hot isostatic pressing and laser powder bed fusion.

Multi-material laser powder bed fusion (LPBF) is gaining a rapidly growing attention within the scientific community, thanks to the remarkable new opportunities that would be offered by the combination of multiple materials into complex 3D shapes, compared to single material LPBF. The possibility to design multi-material components with location-specific properties (e.g., strength, corrosion resistance, thermal or electrical conductivity) would benefit applications spanning across a multitude of industrial sectors. However, for many material combinations, achieving defect-free interfaces appears to be very challenging, due to the same differences in properties that drive the desire to combine these materials.

In this study, we are investigating the combination of CuCrZr with 316L steel, which is known to be a difficult combination to co-process via LPBF due to the high thermal conductivity and laser reflectivity of Cu and the susceptibility of the 316L steel to copper contamination cracking - a type of liquid embrittlement causing cracking by the penetration of liquid copper into the steel grain boundaries. We demonstrate that a subsequent hot isostatic pressing (HIP) treatment can be applied to eliminate the defects present after LPBF. We adopted different approaches and characterized the resulting microstructures and micro-mechanical properties at the interfaces obtained. Our results show that leaving powder unmelted near the interface during the LPBF process and sintering it during the subsequent HIP treatment is a successful strategy for producing defect-free 316L-CuCrZr components with interesting properties, thanks to a fine-grained microstructure near the interface that is retained after HIP, and with the potential to create sharper material transitions. We also discuss the limitations of our approach and how they can be addressed through careful design considerations.

Click on the link to external page read more.